Simplified aquaculture cage and mooring

Learning objectives

Upon completion of this case study, you will be able to:

- Apply additional modeling intents, as draw circle, extrude elements

- Establish routines for transferring experience and information from one analysis case to the next

- Understand, and evaluate strategies, for choosing degree of model details

Introduction

You are to model the same aquaculture facility as in CaseStudy03 in a simplified manner. Through static analysis selected key parameters, as mooring rope tension and buoyancy of the floating collar, should be checked. These parameters are to be compared to corresponding figures from the previous case study, in order to ensure these correspond.

By dynamic analysis, you are to find maximum axial force in selected mooring components and evaluate the results.

Main components of aquaculture facility

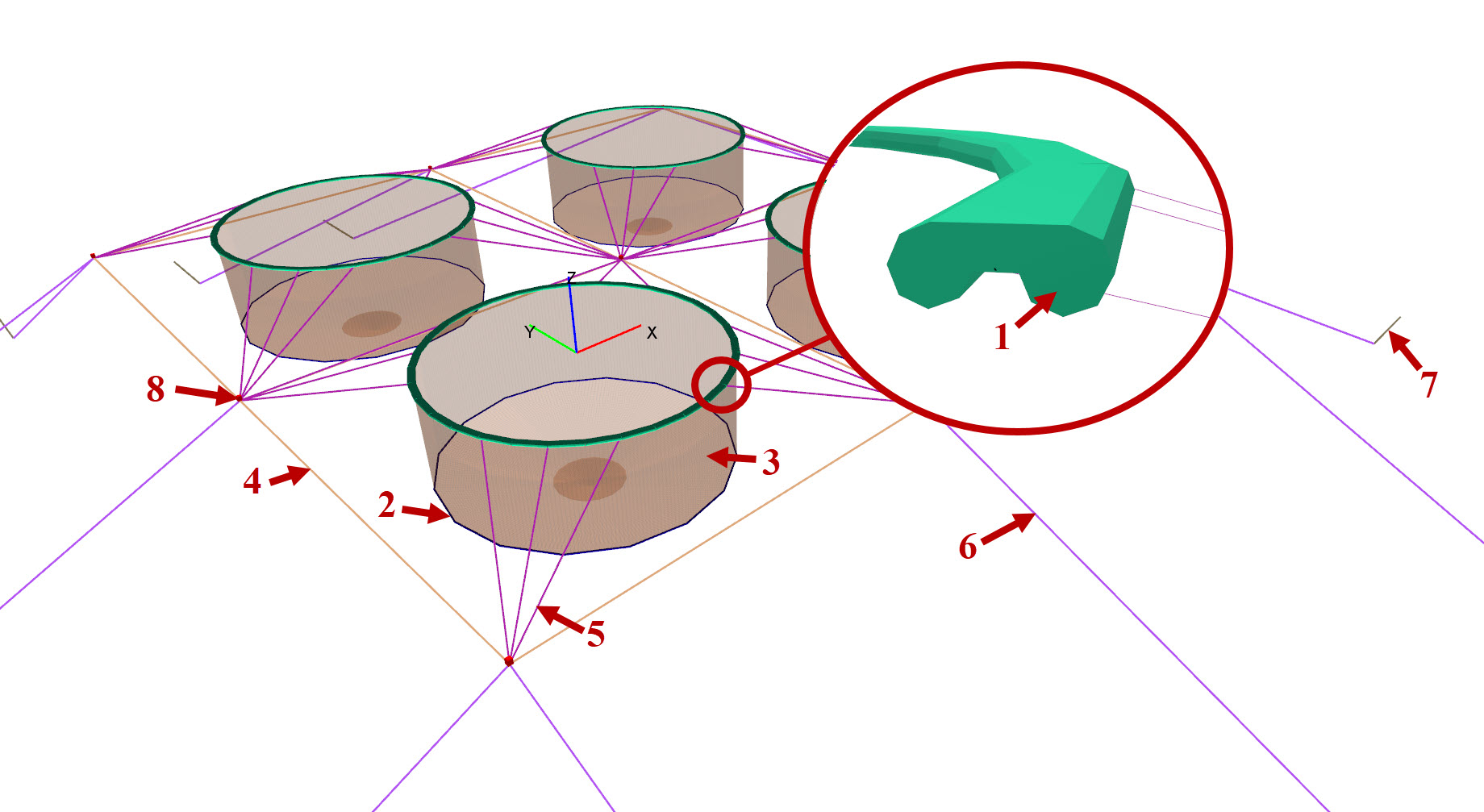

The main simplifications of the aquaculture facility in this case study lies in how the floating collar is modelled and the discretization. Instead of modelling each floating pipe, with brackets, railing post and railing, the floating collar is represented with a double tube. The model and main technical specifications are presented in the figure and table below.

| Component number | Description | Technical data* |

|---|---|---|

| 1 | Floating collar, double tube | PE100, Ø400, SDR16.7, CIR120m |

| 2 | Suspension ring for net pen | PE100, Ø250, SDR11 |

| 3 | Net pen | Sn15.4%, CIR120m, D15m |

| 4 | Frame rope | 64mm, L60m, W60m |

| 5 | Bridle rope | 48mm |

| 6 | Mooring rope | 64mm, L220m |

| 7 | Bottom chain | 32mm, L27.5m |

| 8 | Buoy | L1.0m, W1.0m |

* Abbreviations: PE=polyethylene, Ø=pipe diameter, SDR=pipe diameter/wall thickness, CIR=circumference, Sn=solidity, D=depth, L=length, W=width.